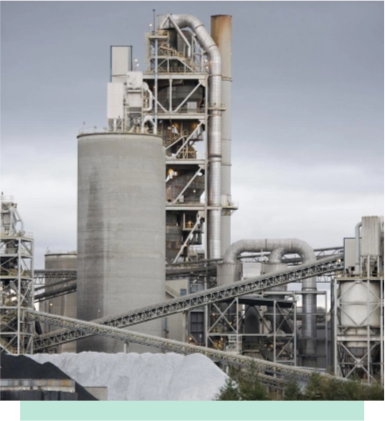

Leverage Advanced Technology With Cement Separators Manufacturers and Suppliers

Our cement separator machines dynamically adjust the separation cut size so that only the finest particles pass through while coarser material is sent back to the mill for further grinding.

- Low-pressure drop across the separator to reduce the overall energy required for achieving optimal separation performance.

- Wear-resistant linings based on high-grade materials for rotor blades and housing that ensure longer service life.

- Advanced aerodynamics that uses optimized airflow patterns for efficient particle separation.

Setting the Global Standard As Cement Separator Manufacturers and Exporters

Experience the transformative difference in cement quality and efficiency with NNT's precision-engineered cement separators.

| Material | : MS-IS2062 /Equivalent |

|---|---|

| Production Capacity | : 3 TPH to 50 TPH |

| Power Consumption | : 10 KW to 220 KW |

| Fuel Type | : Wood Fire/Coal fire /Pallet fire |

| Automatic Grade | : Manual/Semi automatic |

| Drive | : 50 HZ/60 HZ |

| Inclination | : 3 to 6.5 Degree |

Types of Cement Separator Machines

NNT Cement provides various cement separators suited to different cement mill configurations and production requirements. Each separator type serves a distinctive purpose, as mentioned below.

Industries We Serve

While primarily used in cement plants, roller presses have versatile applications across multiple industries. They enhance grinding operations in various high-capacity manufacturing processes.

Mineral Processing

Optimizes particle size for mineral and ore processing.

Steel and Metallurgy

Processes slag into fine particles for supplementary materials.

Energy Sector

Grinds and classifies fuels for efficient combustion in power plants.

Environmental Technology

Separating and recovering valuable materials from industrial waste.

Chemical and Pharmaceutical

Classifies powders for precise product formulation.

Power Generation

Classifying pulverized coal and other fuels for efficient combustion in power plants.

Benefits of Using Cement Separator

Cement separator machines unlock many advantages for manufacturers to boost cement production efficiency quality and achieve sustainability through precise particle size control.

Improved Cement Workability

Control the particle size distribution to enhance the workability and flowability of concrete, facilitating ease of placement and finishing.

Enhanced Plant Reliability

Reliable separator operation minimizes downtime and ensures consistent cement production.

Better Cement Strength

Optimize the proportion of fine particles in the cement, contributing to improved early and late-age strength development.

Reduced Maintenance Costs

Wear-resistant components increase durability, leading to fewer breakdowns and reduced downtime.

Why Choose Us For Cement Separator

Our cement separator machines are built using cutting-edge technology, ensuring precise material separation as we align experts to deliver exceptional quality, innovation, and customer satisfaction.

Innovative Designs

Continuous research and development to incorporate the latest advancements in separator technology, maximizing efficiency and performance.

Predictive Maintenance Software

Advanced predictive maintenance systems analyze operating data to identify potential issues, allowing for proactive maintenance and minimizing unscheduled downtime.

High Fineness Control

Achieve fine cement particle sizes of up to 3500 cm²/g Blaine or more so that your product quality shows high-strength and specialty cement.

Commitment to Sustainability

Prioritizing energy-efficient and environmentally responsible solutions to support a greener cement industry and staying compliant.

Other service we offer

Running a successful cement manufacturing plant requires addressing different needs. Hence, we provide a comprehensive range of services beyond storage solutions. These services help support your entire cement manufacturing process so that your plant operates at peak efficiency, from initial setup to ongoing maintenance.

Your global cement manufacturing partner

We run operations for cement manufacturing plants globally and have a demonstrated history of completing projects in different countries. This means you can benefit from our global expertise and experience in completing cement plant since we understand the unique challenges and opportunities in different markets of the world.

Ready to step forward

3rd Floor, Diamond Complex, SH 41,

Industrial Area, Chhapi, North Gujarat,

India. 385210